Feature Story

Minimizing Flicker in LED Lighting

Applications

Learn How Richtek LED Lighting Solutions Minimize LED Light Flicker

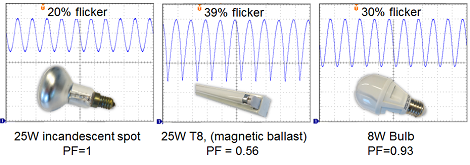

All light sources that ultimately derive their power from the AC mains are likely to flicker. LEDs are particularly worse compared to incandescent lamps because LEDs react quickly to current variation. Most flicker manifest itself as periodic light fluctuation at double the AC line frequency, but incompatibility between lamps and peripheral lighting components can cause random lower frequency flicker as well.

Although 100/120Hz flicker is not perceived

by most humans, it can still lead to

irritation and eye fatigue. Therefore

flicker is one of the key parameters

that need to be considered when it comes

to replacing traditional lights with

efficient, long lasting LED lighting.

Luminaire manufacturers are

eager to solve this problem to win more

customers switching to LED lamps. This

article explains LED flicker phenomena

in relation to driver topology and LED

characteristics and introduces several

Richtek solutions to minimize LED light

flicker.

Flicker Definition

Most often, flicker is calculated by

using the IES RP 16-10 standard method.

For periodic signals

the percent flicker is defined as:

A comparison between different light

sources reveals various flicker percentages.

But how much flicker is allowed?

At this moment, there are no standards

that define the maximum allowed flicker

for LED lamps. But many Luminaire manufacturers

define the percent of flicker to be

less than 30% in the 100Hz/120Hz range.

LED light luminance is directly related

to the current through the LED. To minimize

light flicker, the current variation

through the LED needs to be minimized

as well. It is important to realize

that LED driver topology together with

LED string characteristics play

an important role in the design of low

flicker LED lamps.

Richtek LED Lighting Solutions to Minimize Flicker

If high power

factor is required, a way to minimize

flicker is to increase the converter

output filter capacitance. However,

size and cost need to be considered.

One could also choose LEDs with

higher dynamic resistance, or operate

the LED “closer to the knee” which increases

dynamic resistance as well.

Verification Tool

This

tool is quite simple to build

from readily available components,

and is very useful for checking

the light variation of different

LED lighting applications.

Related Products:

PFC flyback topology:

RT7302,

PFC Buck topology:

RT8487,

Linear

topology:

RT7321 and PFC

MR-16 LED driver:

RT8479

New Products

RT7302

in SOP-8 w/ HV start-up

RT7304

in SOT-23-6 package

Quasi Resonant switching PSR flyback

controllers with

0.99

Power Factor, ideal for

T8,GU10,and

E27

(read more)

RT8487

in TSOT-23-6 package

*

RT8497

built-in 620V/1.8A MOSFET

*

BCM switching LED driver with PFC and

transformer free design

*Coming soon!