Selecting an AC/DC Flyback Controller IC

AC/DC Flyback Controller ICs

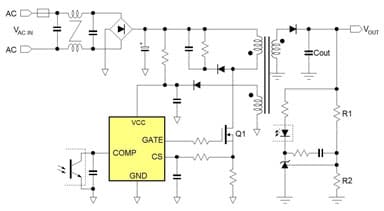

AC/DC Flyback Controllers are used in application where a stable, isolated supply voltage needs to be derived from the AC line voltage. The AC line voltage is first rectified to a high DC voltage. The Flyback supply works similar as a single switch buck-boost, where the inductor is split to form a transformer. The Flyback controller controls the ON time of the high voltage switching MOSFET Q1, which then magnetically energizes the transformer via a current through the primary winding.

When the switching MOSFET is OFF, the transformer energy is transferred to the secondary winding, thereby charging the output capacitor. The transformer will also provide the isolation between primary (hot) side and secondary (cold) side.

The secondary output voltage is sensed with a resistor network, and compared with a reference. The regulation feedback signal is then transferred back via an opto-coupler to the primary side controller, which adjusts the ON time of the MOSFET to maintain a stable secondary output voltage.

The Flyback controller is fed from an auxiliary winding on the transformer.

Flyback supplies can be used in a wide range of applications, from tiny charger adapters to larger main supplies up to 100W.

In applications that require low input power in standby mode, it is necessary to reduce the switching losses of the power components. Most Flyback controllers accomplish this by switching to special burst mode operation in light load conditions. Other important features of Flyback controllers are the protection modes, EMI reduction methods and high voltage start-up circuits for fast start-up.

Flyback controllers for lower power applications like charger adapters often make use of Primary Side Regulation (PSR): These controllers don't need the opto-coupler and feedback network at secondary side; they sense the switching voltage in the auxiliary winding, and derive the secondary output voltage from the aux switching waveform and primary current.

Power supplies with ratings above 75W (like open frame industrial supplies) need to meet power factor requirements, and a PFC boost is added as a pre-conditioning stage. The PFC boost stage will use a PFC controller, which controls the input current to meet PF and current harmonic requirements.

Many isolated off-line LED drivers also make use of Flyback topology, and these LED Flyback controllers use primary side sensing to control the current in the secondary winding for accurate LED current control without the need of an opto-coupler.

AC LED lighting applications have strict requirements on Power Factor (PF) and AC line current harmonics, so most off-line LED Flyback controllers also include functionality to achieve good power factor and low THDi.

You might be interested in...

- Application Notes

- Parametric Search: Get your design started in no time!