Failure Analysis

Failure Analysis Procedure for Customer Complaint Notice

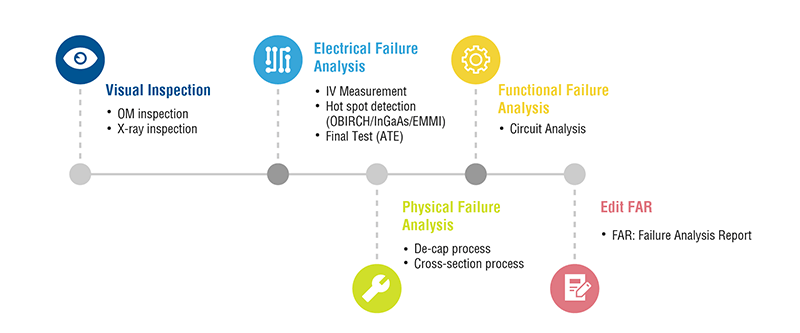

Richtek’s standard failure analysis flow starts from non-destructive check followed by electrical analysis. The destructive analysis is arranged with customer's prior approval if necessary.

We make the analysis plan and collaborate with 3rd party labs located in Hsinchu. They provide tool services with high efficiency, and all the FA results and judgement are concluded by Richtek. The following is a diagram showing Richtek failure analysis process .

Analysis