Reliability

Richtek qualification follows JEDEC standard requirements for consumer and industrial products and AEC for automotive products.

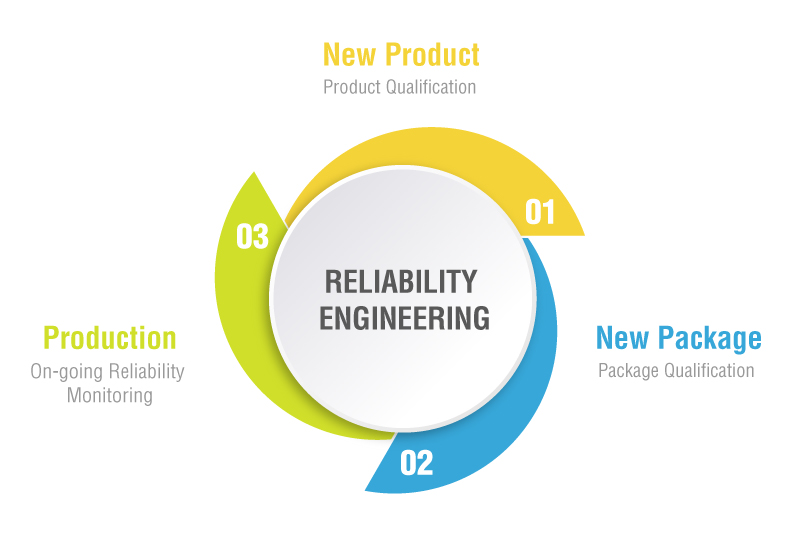

Reliability engineering is applied to qualify packages, products and also to monitor the stability of the manufacturing process.