Reliability Engineering

To ensure product stability and safety in various application environments, Richtek’s reliability engineering strictly follows JEDEC standards (for consumer and industrial products) and AEC standards (for automotive products). We conduct comprehensive reliability qualification for new products and new packages, and continuously monitor the manufacturing process to ensure stability and promptly identify potential risks.

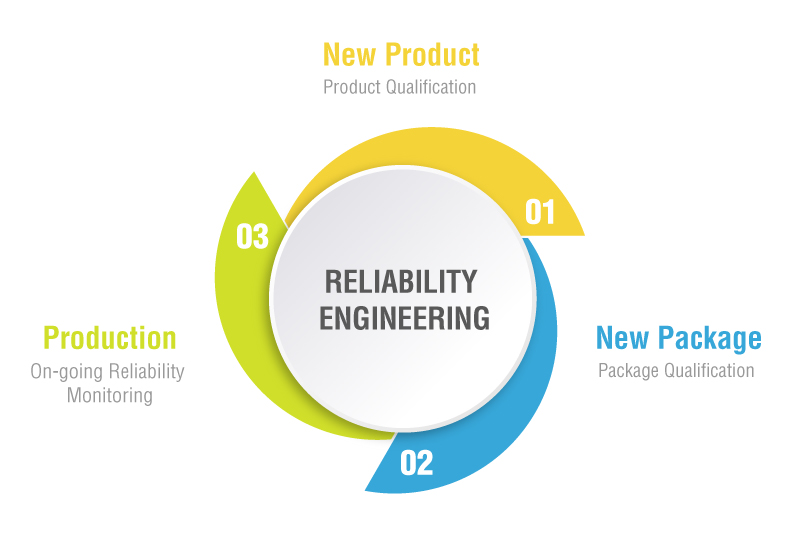

Three Core Processes of Reliability Engineering

- Product Qualification:During the product development stage, rigorous reliability tests are conducted, including high temperature life, temperature cycling, and humidity life tests, to ensure products meet the high �standards required by the market and customers.

- Package Qualification:According to JEDEC standards, various tests such as preconditioning, highly accelerated temperature and humidity stress, temperature cycling, and high temperature storage are �performed to ensure package reliability under different environmental conditions.

- On-going Reliability Monitoring:During mass production, regular sampling and reliability testing are carried out to continuously monitor product quality and adjust production parameters as needed, ensuring each batch maintains consistent high quality.

Our Commitment

Richtek is dedicated to systematic reliability engineering, providing customers with safe, stable, and high-quality products that can be reliably used in various environments.